Stability is one of the most critical performance requirements for a remote control excavator hydraulic system.

Introduction

Stability is one of the most critical performance requirements for a remote control excavator hydraulic system. Unlike conventional excavators operated directly by an onboard operator, remote-controlled machines depend entirely on electro-hydraulic transmission and control logic to convert command signals into physical motion. Any instability within the hydraulic system is immediately reflected in the machine’s behavior.

Unstable motion not only reduces operational accuracy but also increases safety risks, especially in hazardous environments where remote-controlled excavators are most commonly deployed. In practice, stability problems in remote controlled excavators are closely linked to hydraulic system behavior. Addressing these issues requires system-level analysis and targeted hydraulic optimization rather than isolated parameter adjustments.

Why Stability Is More Difficult in Remote Controlled Excavators

Absence of Direct Human Compensation

In conventional excavators, operators subconsciously compensate for system imperfections by adjusting joystick input in real time. In remote-controlled excavators, this natural human feedback loop is weakened or delayed, making the hydraulic system’s intrinsic stability far more important.

Even minor nonlinear effects inside the hydraulic system can cause:Jerky start-stop motion;Oscillation during low-speed operation;Inconsistent actuator response under changing load;These effects are amplified when signal latency and limited visual feedback are introduced.

Typical Stability Problems in Remote Controlled Excavators

Low-Speed Creeping Instability

One of the most common issues is unstable motion during low-speed or fine positioning tasks. Hydraulic actuators may hesitate, suddenly jump, or oscillate when small command inputs are applied.

This behavior is mainly caused by proportional valve dead zones, nonlinear flow characteristics at low valve openings, and insufficient resolution in pressure feedback signals, all of which reduce controllability at low speed.

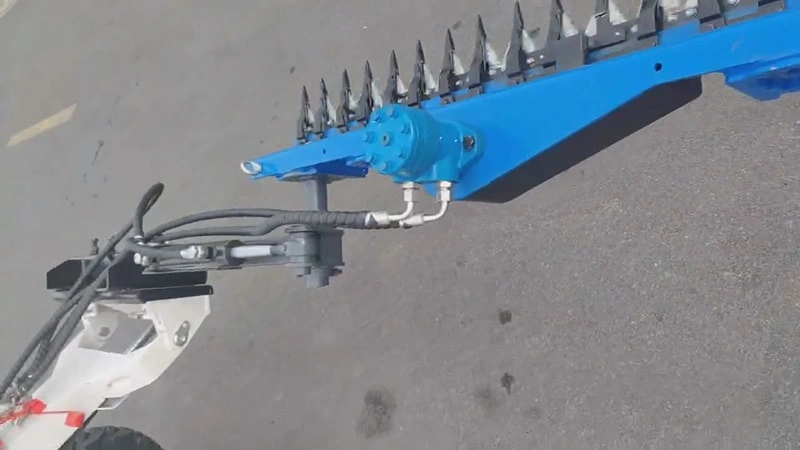

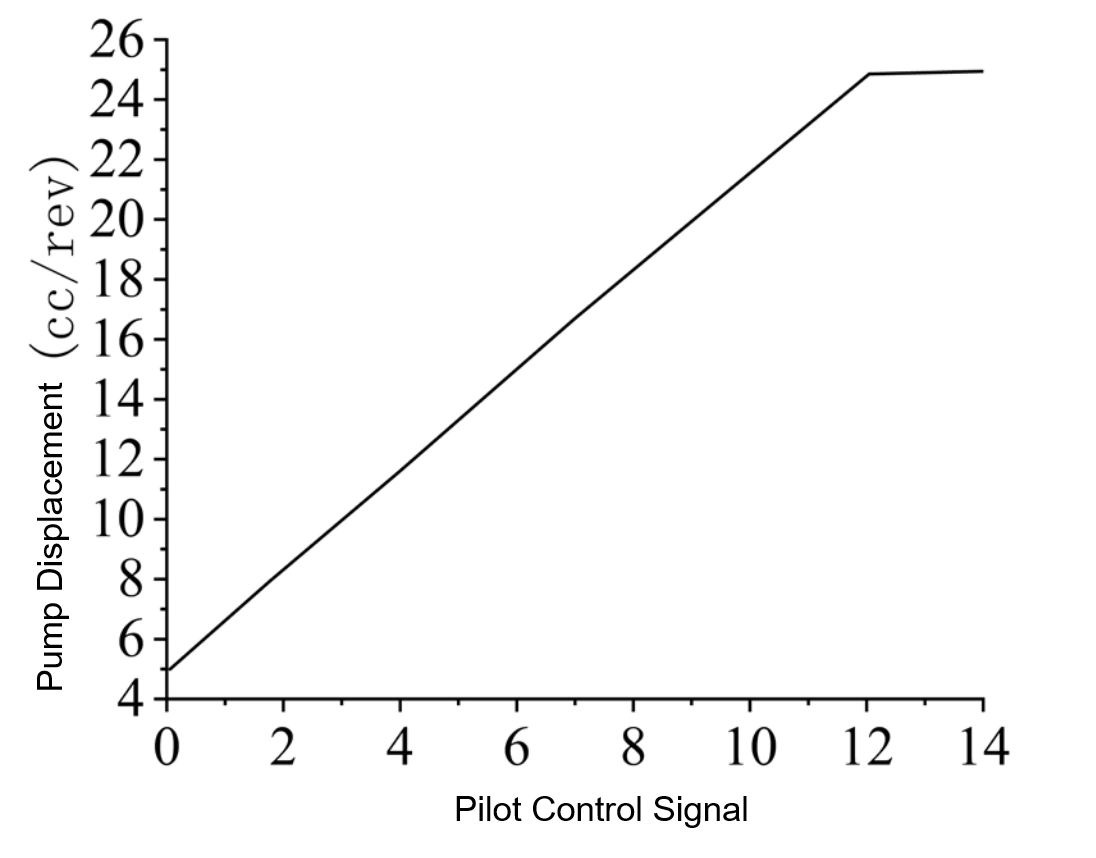

Simulation Model of the Variable Displacement Pump

Flow Regulation Characteristics Curve of the Variable Displacement Pump

Oscillation Under Variable Load Conditions

Excavation resistance changes continuously during digging operations. Without proper compensation, these load variations can cause pressure fluctuations that lead to oscillation or overshoot in cylinder motion.

Remote-controlled excavators are particularly sensitive to this problem because load changes cannot be immediately compensated through direct operator feedback, placing higher demands on intrinsic system stability.

Delayed Response and Overshoot

Signal transmission delays inherent in remote control systems can introduce phase lag between command input and actuator response. When combined with hydraulic nonlinearity, this delay often results in overshoot or repeated correction cycles, reducing operational efficiency.

Simulation Results of Electromagnetic Proportional Pressure Relief Valve

Root Causes at the Hydraulic System Level

Valve Nonlinearity and Dead Zones

Proportional directional control valves are essential components in a remote control excavator hydraulic system. However, dead zones and hysteresis are unavoidable physical characteristics.

Without compensation, these nonlinearities disrupt the relationship between control input and hydraulic output, especially during low-speed operation.

Flow–Pressure Coupling Effects

Hydraulic flow rate is influenced not only by valve opening but also by pressure difference across the valve. As load pressure changes, the same control signal may result in different actuator speeds, undermining system predictability.

Coupling Between Multiple Actuators

Excavators often operate multiple hydraulic actuators simultaneously. Pressure interaction between circuits can introduce coupling effects that degrade overall system stability if not properly managed.

Hydraulic System-Level Solutions for Stability Improvement

Nonlinear Compensation as a Core Strategy

Nonlinear compensation addresses the fundamental mismatch between control input and hydraulic output. By reshaping control signals to counteract dead zones and nonlinear flow behavior, stability can be significantly improved across the entire operating range.

This approach is particularly effective for remote-controlled excavators, where predictable response is essential.

Integrated Feedback Control

Stability improvement requires more than open-loop compensation. By integrating displacement and pressure feedback into the control system, deviations caused by load variation or external disturbance can be corrected in real time.

An optimized feedback structure allows the hydraulic system to maintain stable motion even when remote commands are intermittent or delayed.

System Parameter Optimization

Hydraulic system parameters such as valve gain, damping coefficients, and control bandwidth must be optimized specifically for remote operation. Parameter tuning that works for conventional excavators may not be suitable for remote-controlled platforms.

Simulation-based optimization plays a key role in identifying stable parameter ranges without extensive physical testing.

Validation Through Simulation and Testing

Simulation results indicate that system-level optimization can significantly mitigate stability issues in remote controlled excavators under representative operating conditions. Key improvements include:Reduced oscillation amplitude;Faster settling time;Improved tracking accuracy.

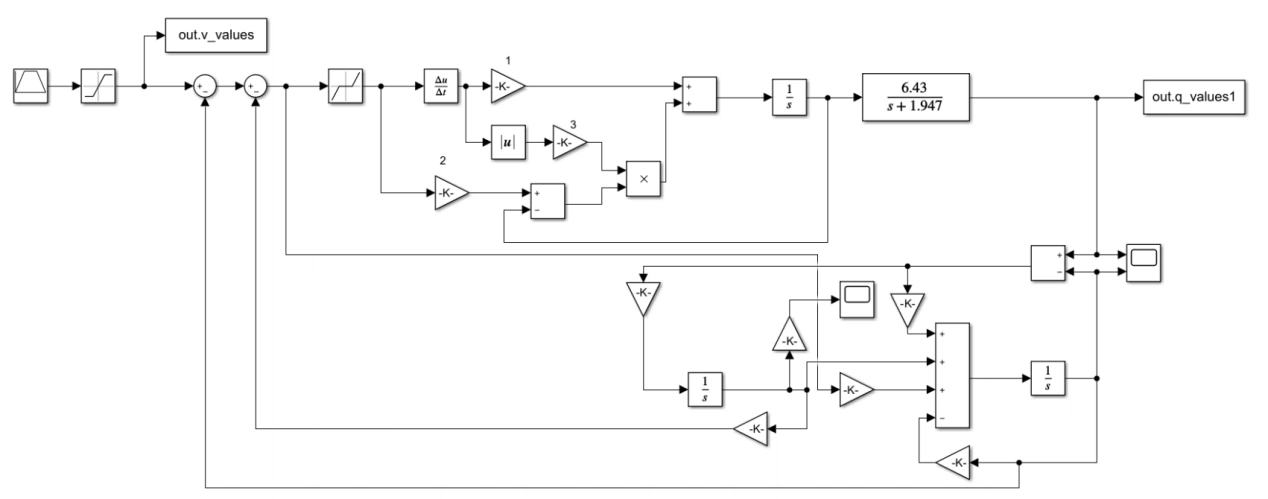

Controller Simulation Model

Practical Benefits for Remote-Controlled Excavator Applications

Safer Operation in Hazardous Environments

Stable hydraulic control minimizes unexpected motion, which is critical when remote-controlled excavators are used in demolition zones, confined spaces, or environments with limited human access.

Improved Precision for Fine Tasks

Enhanced stability allows remote-controlled excavators to perform precision tasks such as grading, trench finishing, and material placement with greater accuracy.

From Engineering Design to Manufacturing Implementation

Transforming hydraulic stability solutions into production-ready systems requires close integration between control design and manufacturing processes. From an engineering and manufacturing perspective, implementing system-level hydraulic optimization strategies ensures robustness, scalability, and suitability for long-term operation in remote-controlled excavator platforms.

By embedding stability-focused design principles into remote control excavator hydraulic systems, manufacturers can deliver equipment that meets both technical and operational demands.

Conclusion

Stability issues in remote controlled excavators originate from hydraulic system nonlinearity, load variation, and signal delay. Addressing these challenges requires a system-level approach that combines nonlinear compensation, feedback control, and parameter optimization.

A well-designed remote control excavator hydraulic system not only improves operational safety but also expands the practical applications of remote-controlled excavation technology. Stability is no longer a secondary consideration—it is a core requirement for modern intelligent excavator systems.